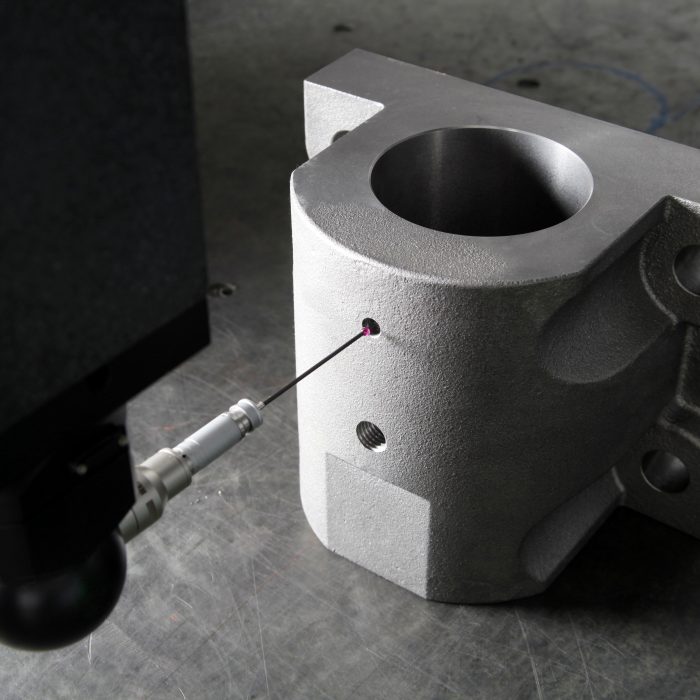

Our CMM technology enables three-dimensional measurement, providing accurate data on component dimensions and tolerances.

We use hardness testing methods to ensure that components possess the appropriate hardness levels for their intended applications.

Depending on the industry and application, we adhere to specific standards such as aerospace or automotive quality requirements.